In today’s highly competitive and rapidly evolving engineering and manufacturing landscape, organizations face the daunting challenge of managing vast amounts of data, design files, documents, and product-related information. This is where engineering data management software, also known as product data management (PDM) software, steps in as a critical tool to streamline processes and ensure data integrity. In this article, Topweb will delve into the significance of engineering data management software and how it plays a pivotal role in improving efficiency and collaboration within engineering and manufacturing sectors.

Engineering Data Management Software: The Backbone of Modern Engineering

Engineering data management software is the backbone of modern engineering and manufacturing operations. It acts as a centralized repository where all critical data, including CAD files, technical specifications, and documents, are stored and organized. In a world where innovation is key, having quick and secure access to this data is paramount. This software not only provides a secure repository but also encompasses a wide array of features that facilitate effective data management and collaboration. Let’s explore these features in detail.

1. Version Control: Ensuring Data Accuracy

One of the primary functions of engineering data management software is version control. This is where the software truly shines. With complex projects involving numerous stakeholders, keeping track of changes and ensuring the use of the correct version is a critical task. Engineering data management software solves this problem by meticulously tracking each version and revision of a document or CAD file. The engineering data management software comes into play here, ensuring that the right version of data is used at every stage of product development, thus averting the risks associated with outdated or incorrect data.

2. Access Control and Security: Safeguarding Intellectual Property

Security is of utmost importance in the world of engineering and manufacturing. Organizations must ensure that only authorized personnel have access to sensitive engineering data and proprietary designs. This is where the data management software reappears, as these tools offer robust access control and security features. With these in place, organizations can rest assured that their intellectual property is protected.

3. Collaboration and Workflow Management: Streamlining Processes

Modern engineering projects are rarely the work of a single individual. Collaboration is key, and engineering data management software offers features that enable teams to work seamlessly on designs and documents. These solutions come equipped with workflow management features that streamline the review and approval processes. Engineering data management software ensures that the right individuals are involved at each stage of the workflow, contributing to more efficient collaboration.

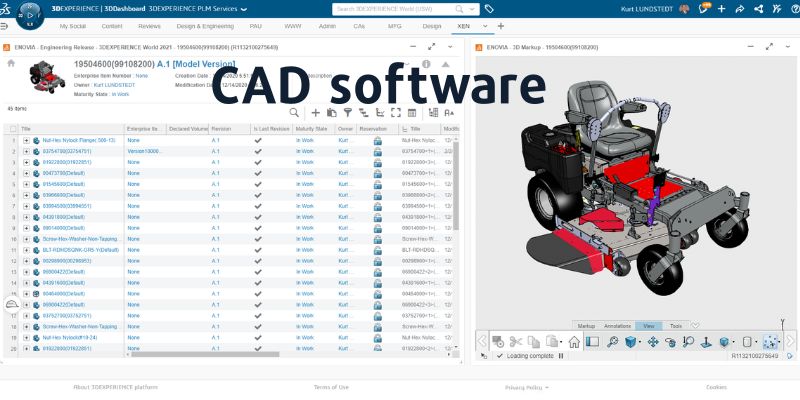

4. Integration with CAD and Other Tools: A Seamless Design Process

For engineers, CAD software is their canvas. To improve efficiency, PDM software integrates seamlessly with CAD tools, allowing engineers to check designs in and out directly from their CAD environment. This close integration enhances the design process and ensures that design changes are automatically tracked and controlled.

5. Search and Retrieval: Finding What You Need

Efficient search and retrieval of engineering data and documents are essential for productivity. Whether it’s locating a specific design document or a technical specification, engineering data management software simplifies the process. Users can use various search criteria to quickly locate the information they need, making their workflow more efficient.

6. Change Management: Documenting and Approving Changes

Change is a constant in engineering. Managing changes to designs and documentation is a delicate process, and engineering data management software plays a pivotal role in this domain. These tools support the change management process, ensuring that changes are properly documented, approved, and implemented. With engineering data management software, organizations can effectively track and control changes, reducing the risk of errors and ensuring compliance with company standards.

7. Audit Trail and History: Accountability and Compliance

Maintaining an audit trail is crucial for accountability and compliance. Engineering data management software ensures that every action, modification, or access to data is logged. This audit trail is invaluable when it comes to understanding the history of a product’s development and resolving disputes. It is a testament to the software’s role in ensuring data integrity and compliance with industry-specific standards and regulations.

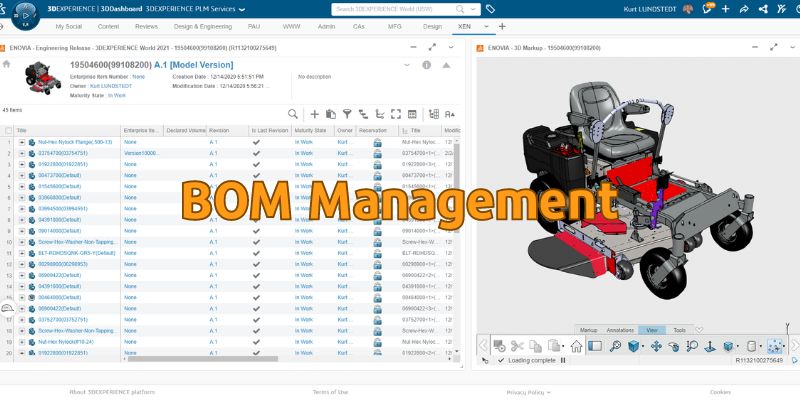

8. BOM Management: Streamlining Production

The Bill of Materials (BOM) is a critical component of product development and manufacturing. Engineering data management software often includes features for managing and optimizing the BOM. This ensures that the right components are sourced and assembled, reducing the risk of costly errors during manufacturing.

9. Compliance and Regulatory Support: Meeting Industry Standards

Many industries have specific standards and regulations that must be adhered to. Engineering data management software provides features to help organizations comply with these standards, such as ISO or AS9100. By incorporating these compliance features, the software reinforces the organization’s commitment to quality and safety.

Selecting the Right Engineering Data Management Software

Choosing the right engineering data management software is a crucial decision that depends on an organization’s specific needs, size, and budget. The software frequently resurfaces in discussions about selecting the right solution. Siemens Teamcenter, PTC Windchill, Dassault Systèmes ENOVIA, Autodesk Vault, and SolidWorks PDM are among the popular choices. These solutions offer a wide range of features and scalability, making them suitable for a variety of engineering and manufacturing environments.

Conclusion: The Future of Engineering Data Management

In the fast-paced world of engineering and manufacturing, the role of engineering data management software cannot be overstated. It serves as the bedrock of efficient, secure, and collaborative product development. As technology continues to evolve, so too will the capabilities of engineering data management software. With advancements in AI, machine learning, and cloud-based solutions, the future promises even more streamlined and intelligent ways of managing engineering data.

In conclusion, engineering data management software, with its robust features for version control, security, collaboration, and compliance, ensures that the right data is accessible to the right people at the right time. This not only improves efficiency but also minimizes errors and accelerates the product development lifecycle. This data management software epitomizes the foundation upon which modern engineering and manufacturing success is built, making it an indispensable tool for organizations looking to stay competitive in today’s dynamic marketplace.